|

Saky Steel CO., LTD

|

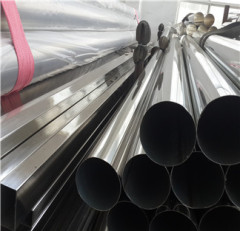

stainless steel pipe polished

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Oil,Medical Machines Water Conservancy Projects And So

1.Detailed Product Description

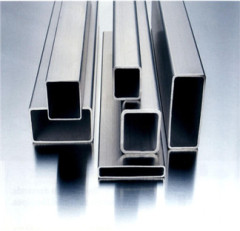

Size | (2-630) x (0.3-50) x (800 - 13000)mm | |

Material Grade | 304, 304L, TP304, TP304L, 316L, TP316L, 321, F321, etc. | |

Standard | ISO 9001/ ASTM A269/ A270/ A312/ A213, GB/T 14976/ GB/T 13296, etc. | |

Description | Process Method | Cold Drawn |

Surface Finish | Treatment: Annealing and Pickling, Wire Drawing or Hairline Finish | |

Ends Finish | Plain Ends or Beveled Ends | |

Test | Eddy Current/ Hydrostatic/ Ultrasonic/ Intergranular Corrosion Or according to customers' request | |

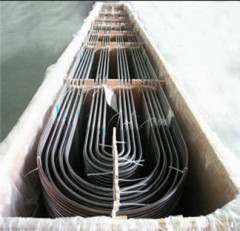

Application | For use in the Petroleum, Chemical, Chemical fiber, Medical Machinery, Aerospace, Paper, Food, Shipbuilding, Environmental Protection, Boilers, Heat Exchangers, Pressure Vessels, Condensers, Water, Electricity and other industries. | |

Packing | Each in PVC bags, Bundles with knitted plastic bags, Wooden cases or according to customers' request | |

2. stainless steel chemical composition

Reference Table of Chinese-foreign Stainless Steel Brand

No | GB | JIS | ASTM | Chemical Composition(wt%) | |||||||

C | Si | Mn | P | S | Ni | Cr | other | ||||

1 | 1Cr 18Ni9Ti | ≤0.12 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~10.00 | 17.00~19.00 | Ti:(c-0.02)-0.08 | ||

2 | 0Cr 18Ni10Ti | SUS321 | 321, S32100 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 9.00~12.00 | 17.00~19.00 | Ti≥5c% |

3 | 0Cr 18Ni9 | SUS304 | 304, S30400 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~11.00 | 17.00~19.00 | |

4 | 00Cr 19Ni10 | SUS304L | 304L, S30403 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~10.00 | 18.00~20.00 | |

5 | 0Cr17 Ni12Mo2 | SUS316 | 316, S31600 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 10.00~14.00 | 16.00~18.50 | Mo:2.00-3.00 |

6 | 00Cr17 Ni14Mo2 | SUS316L | L316L, S31603 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 12.00~15.00 | 16.00~18.00 | Mo:2.00-3.00 |

7 | 0Cr18Ni 12Mo2Ti | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 11.00~14.00 | 16.00~19.00 | Mo:1.80-2.50 | ||

8 | 0Cr2 5Ni20 | SUS310S | 310S, S31008 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 19.00~22.00 | 24.00~26.00 | |

| Production | Stainless steel seamless pipe/tube |

| Technique | Seamless (Cold Drawn/Cold Rolling) |

| Standard | GB/T 14975-2002,GB/T 14976-2002,GB 13296-2007,GB 9948-2006,GB 5310-95 |

| ASTM A312, ASTM A213, ASTM A269 and ASTM A511, ASTM A789 and ASTM A790 | |

| JIS 3463 and JIS 3459 | |

| DIN 2462, DIN 17458 and DIN 17456 | |

| GOST 9941 | |

| Out Diameter | 1/8"~32",6mm~830mm |

| Wall Thickness | SCH10S,SCH40S,SCH80S,SCH160S,1mm~60mm |

| Material | TP304,TP304L,TP304H,TP316,TP316L,TP316Ti,TP309,TP310S,TP314, |

| TP317L,TP321,TP347H,904L,S31803,S32205,S32750 etc. | |

| Length | 1-12m or as customers required |

Surface treatment | polishing,annealing,bright annealing and acid pickling |

| Package | 1. Bundle packing. |

| 2. Bevelled end or plain end as buyer's required. | |

| 3. Marking: as per customer's requests. | |

| 4. Plastic bag wrapped outside the pipe. | |

| 5. Pack into plywood case. | |

| 6. Plastic caps at ends. |

Chemical Composition

| NO. | STAN DARD | GRAND | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu | Ti | Nb |

| 1 | ASTM A312 | TP304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 18.0 -20.0 | 8.0 -11.0 | |||||

| 2 | ASTM A312 | TP304H | 0.04 -0.10 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 18.0 -20.0 | 8.0 -11.0 | |||||

| 3 | ASTM A312 | TPP304L | ≤0.035 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 18.0 -20.0 | 8.0 -12.0 | |||||

| 4 | ASTM A312 | TP316L | ≤0.035 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 16.0 -18.0 | 10.0 -14.0 | 2.00 -3.00 | ||||

| 5 | ASTM A312 | TP316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 16.0 -18.0 | 11.0 -14.0 | 2.00 -3.00 | ||||

| 6 | ASTM A312 | TP317 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 18.0 -20.0 | 11.0 -14.0 | 3.00 -4.00 | ||||

| 7 | ASTM A312 | TP317L | ≤0.035 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 18.0 -20.0 | 11.0 -15.0 | 3.00 -4.00 | ||||

| 8 | ASTM A312 | TP321 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 17.0 -19.0 | 9.0 -12.0 | 5* C+N) ~0.7 | ||||

| 9 | ASTM A312 | TP347H | 0.04 -0.10 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 17.0 -19.0 | 9.0 -12.0 | 8*C ~1.10 | ||||

| 10 | ASTM A789 | S31803 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤ 0.020 | 21.0 -23.0 | 4.50 -6.50 | 2.50 -3.50 | 0.08 -0.20 | |||

| 11 | ASTM A789 | 904L | ≤0.02 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.035 | 19.0 -23.0 | 23.0 -28.0 | 4.00 -5.00 | 1.0 -2.0 | |||

| 12 | ASTM A312 | TP310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 24.0 -26.0 | 19.0 -22.0 | |||||

| 13 | ASTM A312 | TP314 | ≤0.025 | 1.5 -3.0 | ≤2.0 | ≤0.045 | ≤ 0.030 | 23.0 -26.0 | 19.0 -22.0 | |||||

| 14 | DIN17 458-85 | 1.4301 | ≤0.07 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.015 | 17.0 -19.5 | 8.5 -10.5 | ≤0.11 | ||||

| 15 | DIN174 58-85 | 1.4306 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.015 | 18.0 -20.0 | 10.0 -12.5 | ≤0.11 | ||||

| 16 | DIN174 58-85 | 1.4404 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.015 | 16.5 -18.5 | 11.0 -14.0 | 2.00 -2.50 | ≤0.11 | |||

| 17 | DIN17 458-85 | 1.4401 | ≤0.07 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.015 | 16.5 -18.5 | 10.5 -13.5 | 2.00 -2.50 | ≤0.11 | |||

| 18 | DIN17 458-85 | 1.4541 (321) | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.015 | 17.0 -19.0 | 9.0 -12.0 | 5*C -0.70 | ||||

| 19 | DIN17 458-85 | 1.4550 (347H) | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.015 | 17.0 -19.0 | 9.0 -12.0 | 10*C ~1.00 | ||||

| 20 | DIN17 458-85 | 1.4462 (2205) | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.015 | 21.0 -23.0 | 4.5 -6.5 | 2.50 -3.50 | 0.10 -0.22 | |||

| 21 | DIN17 458-85 | 1.4539 (904L) | ≤0.02 | ≤0.70 | ≤2.0 | ≤0.035 | ≤ 0.015 | 19.0 -21.0 | 24.0 -26.0 | 4.00 -5.00 | ≤0.15 | 1.20 -2.00 | ||

| 22 | DIN17 458-85 | 1.4841 (314) | ≤0.20 | 1.50 -2.50 | ≤2.0 | ≤0.045 | ≤ 0.030 | 24.0 -26.0 | 19.0 -22.0 |